- Sectors

- Aerospace & Defense

- Big science

- Biotechnology

- Fintech

- Work at ARQUIMEA

- Insights

IMAGE: January 28, 2017.Successful launch of the Hispasat’s Small-GEO satellite H36W-1 from Kourou

Part of ESA’s ARTES-11 (Advanced Research in Telecommunications Systems) program to develop a general-purpose small geostationary satellite platform, the H36W-1 incorporates REDSAT, an advanced regenerative payload consisting of a novel active Electronically Steerable Antenna (ELSA) with reconfigurable beams that, together with the on-board processor, improves the efficiency and services offered by the satellite. The antenna can be controlled electronically from the Earth and reoriented at any point during the lifespan of the satellite, granting the flexibility to adapt its coverage to mission changes that may occur after launch, while still in orbit. ARQUIMEA’s contribution consisted of the development of a configurable set of ASICs to provide the ELSA antenna with control and management capabilities of the RF subassemblies for versatile beam configuration, as well as housekeeping telemetries of the active elements.

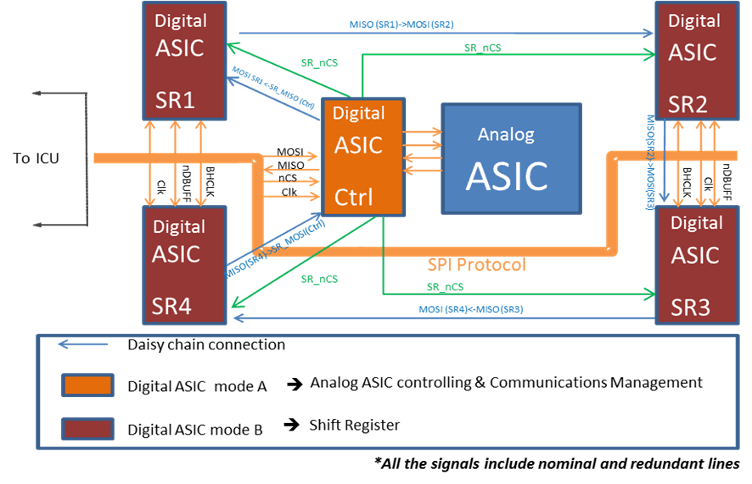

The ASIC set composed by an analog ASIC ARQ-RSA02 and at least two digital ASICs ARQ-RSB01, is interfaced with the Antenna’s Control Unit through SPI and allows internal communication between its composing elements under a configurable daisy-chain arrangement to provide antennas coefficients (attenuation and phase shift), high-voltage control of power amplifiers, as well as current and voltage telemetries. ARQ-RSA01 is a CMOS device including high-voltage features and designed by ARQUIMEA using On-Semi’s I3T80 350nm technology. ARQ-RSB02 is a full CMOS device designed using the DARE180 rad-hard standard cell library belonging to IMEC and based on UMC’s 180nm technology.

An international supply chain coordinated by ARQUIMEA and composed by IMEC for the digital back-end and foundry services, Fraunhofer IMS for the wafer probing and die conditioning, and HIREX for the qualification tests, allowed the procurement of thousands of qualified dice for their integration into a Multi-Chip Module assembled by INDRA.

The REDSAT ASIC set project was the first space microelectronics project awarded to ARQUIMEA involving the design of two complex integrated circuits for an actual flight mission consisting of a GEO commercial communications satellite operated by the Spanish company Hispasat. The chips were part of a new concept of antenna (ELSA) integrated in a brand new satellite bus, the Small-GEO platform developed by OHB.

The project team is a key factor to face important challenges. In this sense, it requires a perfect balance between the resources, managers and engineers to ensure on the one hand compliance with the target requirements and expected performance under strict PA/QA protocols, and on the other hand to meet the objectives considering planning and budget constraints, together with potential risks. Any space ASIC development shall follow a strict working methodology to grant the success of the project. In the case of the REDSAT ASICs, some back-up solutions including external rad-hard components were considered in case of unexpected behaviour of critical embedded analog blocks.

DESIGN

The ASIC set composed by an analog ASIC ARQ-RSA02 and at least two digital ASICs ARQ-RSB01 is designed to operate under a configurable daisy chain and provides:

The ASIC set procured in die form according to the ESCC-Q-ST-60-05C standard for hybrid circuits was assembled into an MCCM module.

IMPLEMENTATION AND ACCEPTANCE

The wafer manufacturing was performed using a full-mask approach under the UMC180L technology. On-Wafer Acceptance Test (WAT) including Scan Electron Microscope, Electrical Die Sort, dicing and die visual inspection based on the MIL-STD-883 TM2010 standard allowed the selection of the Flight Models.

In parallel, a user-Lot Acceptance Test (user-LAT) or a qualification of the die and associated assembly process was performed by the subcontracted test house to ensure that defect allowance was acceptable to validate the reliability figures defined by the customer. Those were obtained through radiation characterization, endurance, environmental and mechanical testing.

The Radiation characterization, as well as the qualification, were successful. Thousands of flight models were selected from the WAT and delivered to the customer.

In 2015 and 2020, new lots were procured by Airbus for the satellite QUANTUM (operated by Eutelsat) and other communications satellite, respectively.